![]()

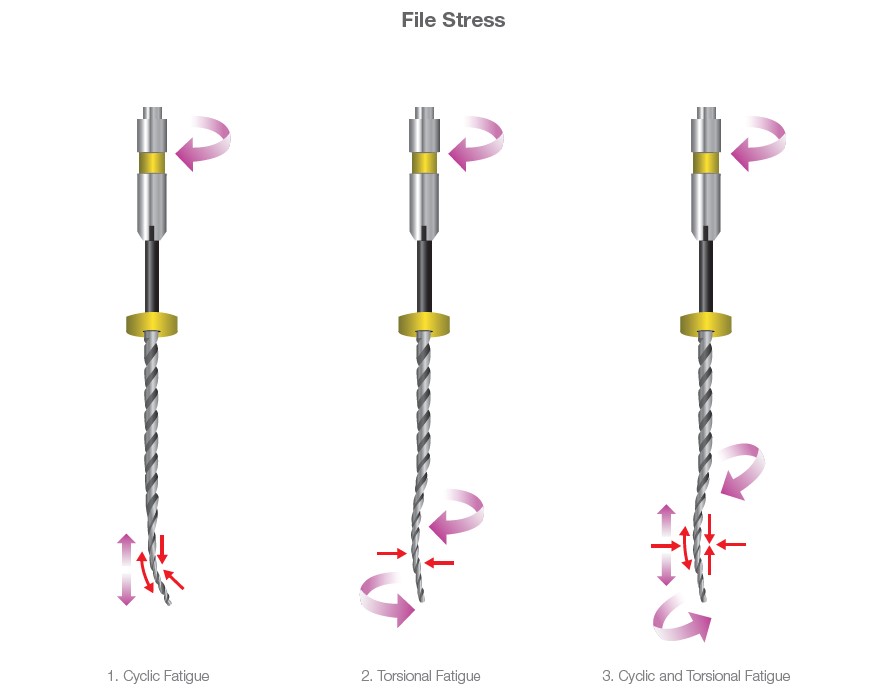

When instrumenting, endodontic files are always exposed to mechanical forces such as friction resistance and/or clamping force in the root canal, which act on the file as torque during rotary preparation.

This resistance counteracts the drive torque of the endomotor and can cause the file to twist (torsion). Under certain conditions (torsion strength and frequency of repetition) this may cause the file to break.

Therefore, the torque acting on the file must be limited. Such a limitation can be realized in different ways:

- Controlling the pressure acting on the file manually, i.e. working "with feeling“. This is relatively feasible when the preparation is done by hand. However, when a preparation motor is used, the tactile sensation is basically lost. Cyclically rotate the file backwards (opposite to the cutting direction) in order to relieve the stress.

The most pragmatic application of this method is relieving the file periodically after certain time intervals or rotational angles.

This occurs, for example, in reciprocating modes of operation.

Periodic motions may not be very original, but they are easy to realise as far as engineering is concerned.

One disadvantage is that the individual situation of a root canal isn’t taken into consideration.

- The torque acting on the file (impeding) can be measured. Hence, it is possible to automatically relieve the file only when this is really necessary and expedient. In other words, the actual stress acting on the file controls the cycle (torque-provoked reversal of rotation direction). This function is called Auto Torque Reverse and was realized for the first time in the world in Morita’s TriAuto ZX, later also in the endodontic motors DentaPort ZX and TriAuto mini as well as the treatment unit Soaric.

Since this method has proven its worth, endodontic motors made by other manufacturers are increasingly being fitted with Auto Torque Reverse functions.

- Nonetheless, there are qualitative differences between the different Auto Torque Reverse functions, which become evident in connection with such criteria as, for example, measuring accuracy and speed of the control circuit.

Also, such quantitative criteria as length of the measuring intervals or reverse rotation of the file affect not only the time needed for the therapy but also the effectiveness and consequently, the safety of the reversal of the direction of rotation.

- It is in this respect that Morita once again is setting a new standard with Optimum Torque Reverse. Although the OTR function also uses torque-provoked reversal of the direction of rotation, OTR requires only a very small angular rotation of the file to provide safe feedback about its current stress.

Accordingly, you can work with optimized rotation angles both when the file is rotating in the direction of cutting and the reverse direction. Material tests have shown that nickel-titanium files can tolerate torsion of half a rotation (180°) in the direction of cutting. In the reverse direction of rotation, a quarter rotation (90°) is needed to release the file.

Extensive experiments and tests in dental practices with different file systems and brands have confirmed these values.

Tri Auto ZX2 and DentaPort with OTR continues to be a universal system for almost all file systems.

Article Published in May/June 2023 Dental Solutions